PAGE CONTENTS

Objectives

The objective of the current activity is to design, analyse, manufacture and test an Engineering Model of a Non-Explosive Actuator (NEXA), to be used in Hold-Down and Release Mechanisms (HDRM) of future telecom platforms.

The Technology Readiness Level (TRL) target at the start of the activity is TRL 5 (i.e. prototype demonstration in relevant environment).

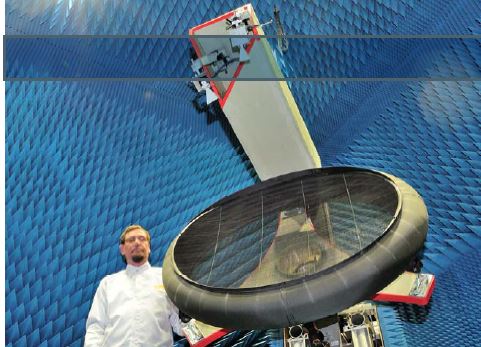

NEXA mechanism (Credit: Spin.Works, S.A.)

The scope of activities for the NEXA mechanism is performed under a joint EM/QM approach. The mechanism is developed as a qualification model (QM) up to DDR, while the production, assembly and testing are carried on an engineering model (EM).

Challenges

Four critical parameters for the development of the mechanism are identified:

- Reliability, self-generated release shock, reusability and release time (repeatability and simultaneity). These parameters guide the development of NEXA. From the start of the project, three features are identified as highly desirable: ultra-low self-generated shock and reusability. The incorporation of these features poses a challenge for the design of the mechanism.

Also of great concern during the development process is the need to conservatively avoid any pre-existing intellectual property rights. A large number of existing patents in the field has been analysed in order to steer the development process away from previously patented concepts, and ensure patentability of the concept developed in the context of this activity. This adds additional constraints on the design space to an ambitious fast-acting ultra-low-shock reusable design.

Plan

All the planned milestones of the project are completed: Preliminary design review (PDR), detailed design review (DDR), test readiness review (TRR) and the post-test review (PTR).

The scope of activities for the NEXA mechanism is performed under a joint EM/QM approach. The mechanism is developed as a qualification model (QM) up to DDR, while the production, assembly and testing are carried on an engineering model (EM).

As part of the activity’s initially planned tasks, an implementation plan is defined, laying forth the future activities required for the completion of:

- Successful qualification testing of a QM.

- Development up to a commercially available product and the delivery of a FM

Current Status

A QM/EM NEXA mechanism has been designed, manufactured and tested in representative conditions. In its final configuration, the mechanism performed successfully in all the planned tests. The mechanism is developed as a qualification model (QM) up to DDR, and the production, assembly and testing are carried on an engineering model (EM).

A fast-acting, fully re-usable, ultra-low shock HDRM is a somewhat demanding mechanism to design. During the course of the present activity setbacks had to be overcome in order to refine the function of the mechanism and bring it to a TRL of 4-5, with a severe impact on project schedule.

Non-conformances arose from the underestimated effect of intra-filament friction in the resulting elastic properties of a multifilament cable. The elastic snapback of the cable has an impact on the function of the mechanism, and found to be lower than predicted at DDR. This increases the operator force necessary for the reset function of the mechanism. The built-to-spec multi-stranded cable configuration was abandoned in favor of a COTS wire rope cable, with flawless operation and successful testing afterwards.

Companies