PAGE CONTENTS

Objectives

The project’s goal was to develop electro-photonic building blocks for next-generation telecommunication payloads, focusing on frequency downconversion between feeder and user links in future Q/V band communications. The EPFCV2 photonic chip performs downconversion from the Q/V band (up to 50 GHz) to the Ka band (around 30 GHz), designed to be frequency-agnostic for multiple applications. This allows integration into Very High Throughput Satellites (VHTS) targeting 1TB/s data rates. The device leverages the advantages of photonic-enabled payloads, including reduced mass, power consumption, and cost, while enhancing flexibility and capacity.

The new satellite payload concept requires numerous feeds or phased array systems, which involve many converters and stable clock distribution. Additionally, laser communication for inter-satellite links is emerging as a secure, high-data-rate solution, beneficial for fleet operations. This technology has been recently demonstrated for GEO-LEO relay, LEO constellations, and lunar communication. The project consortium includes Antwerp Space (AS) as the prime contractor, Fraunhofer HHI institute as the photonic integrated circuit (PIC) foundry partner, and Alter UK for packaging the PIC

Challenges

The project aimed to deliver a high bandwidth, low noise and power efficient frequency downconverter based on integrated photonic technology. The first challenge was to integrate on the same chip a high frequency I-Q modulator, a laser source and on a second chip a high bandwidth photodiode and a semiconductor optical amplifier. When the project started, these devices (modulators, lasers) were realized in separate chips. Integrating them in the same chip enabled a more efficient device, the manufacturing of a device with such level of integration was a pioneering work. An additional challenge was the development of efficient driving electronics for the PIC.

System Architecture

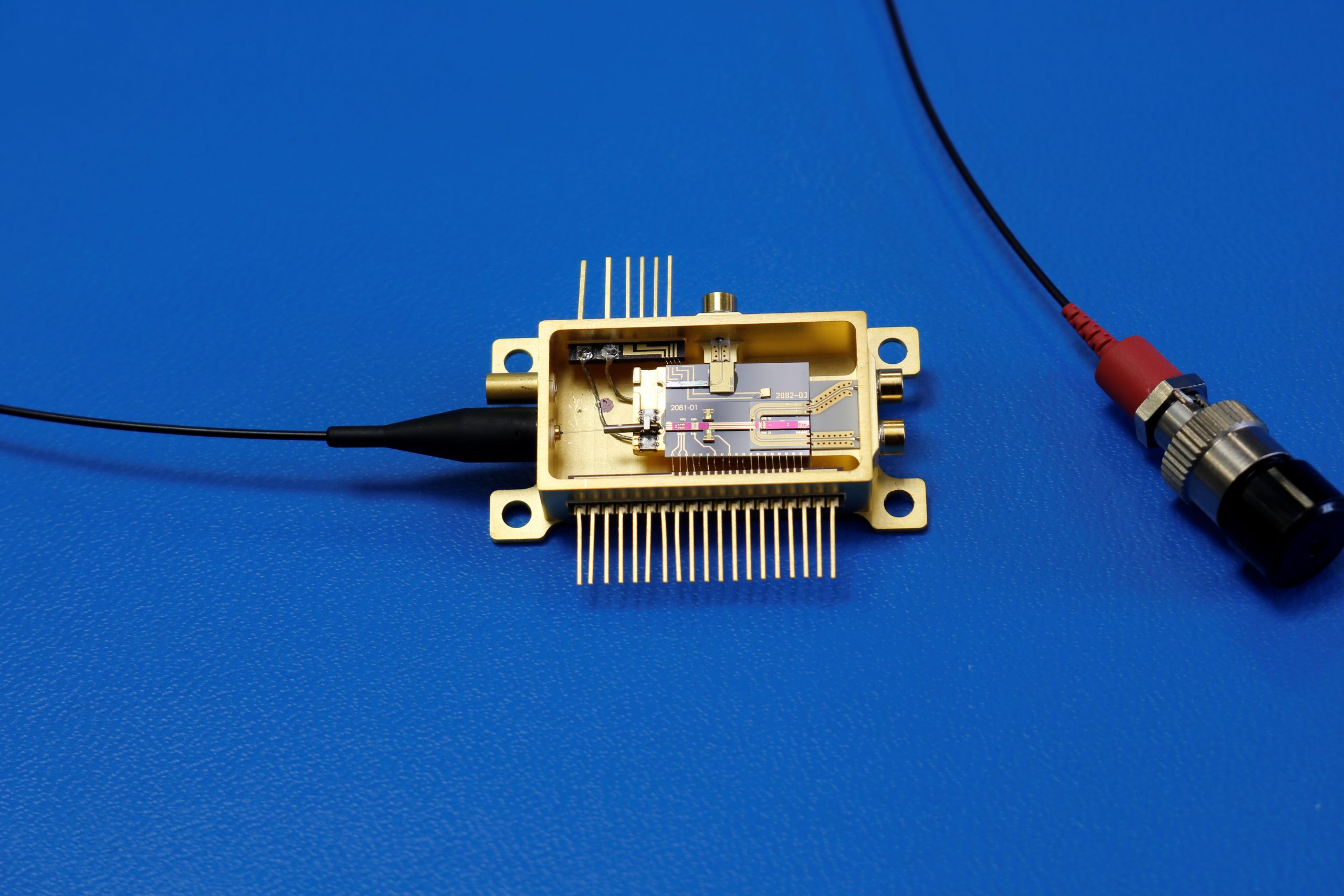

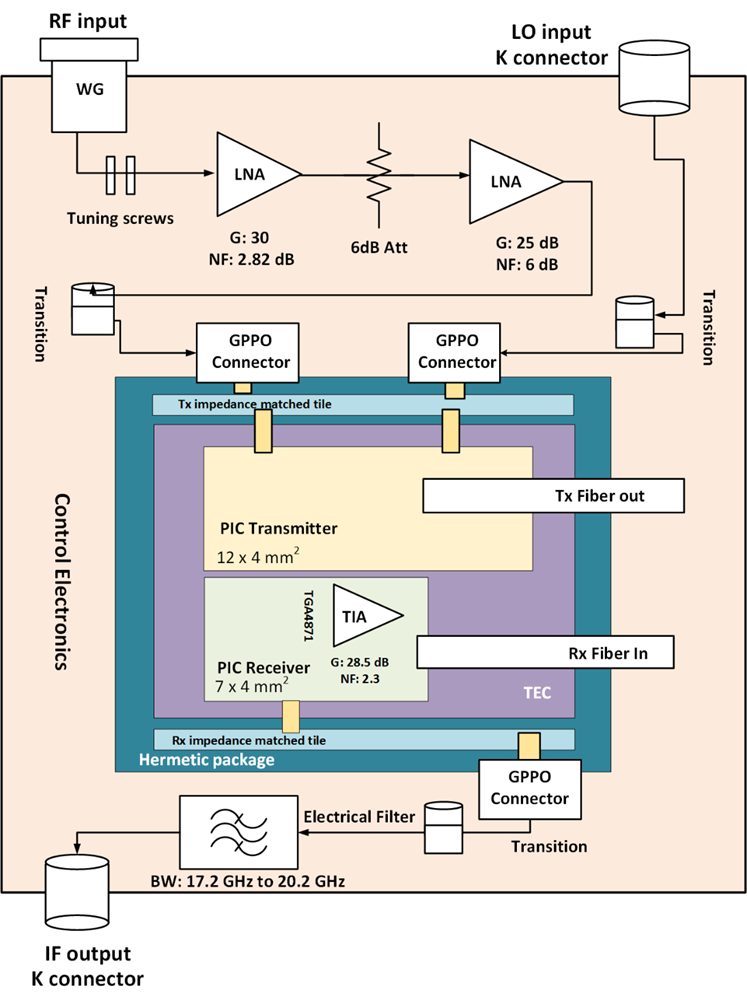

The system architecture is detailed in the figure. The equipment is comprised of an RF board, a control board and the packaged photonic circuits. The RF board deals with the inputs, Rf signal and Local oscillator (LO) and the intermediate frequency (IF) output. The PPIC hosts two PICs: a transmitter and a receiver. The transmitter encodes the RF signal and the Lo in a light beam. The light signal is couple into an optical fibre leaving the equipment. The optical signal can be distributed into the spacecraft with significantly lower losses and ease of routing than a coaxial cable. The PIC receiver converts the optical signal back to the electrical domain into a downmixed IF.

Plan

The project milestones were: System Requirement review, where the needs of the space sector in terms of functionality and performance were analysed and translated into requirements for the photonic IC, the packaging, the RF and control boards. Then the best possible technological platform had been selected in the next milestone, Technology Selection Review. The work was then split in three, HHI was in charge of the PIC development, Alter of integration and packaging and Antwerp Space took over the system engineering tasks, development of electrical boards and project management. Once the pieces of hardware had been manufactured an integrated, they could be tested.

Current Status

The project has been completed and a Demonstrator has been realized. Several challenging and pioneering activities have been accomplished. The development of RF interposers with a 50 GHz bandwidth for packaging, high frequency electro-optic interfaces have been realized. On the Integrated photonic side, a very innovative chip has been manufactured, with the co-integration of building blocks that were not integrated before on the same chip. Leading to a strong improvement in the manufacturing process.