PAGE CONTENTS

Objectives

This project is focusing on the development of novel waveguide harness solutions that provide mass savings in the order of 20% or more without penalty of mechanical and RF performance compared with existing implementations. A detailed review of present harness designs is performed to identify the individual mass contributions of the related hardware, as e.g. waveguide runs, interconnections and assembly material. Subsequently, techniques such as wall thickness reduction, material selection, fixation methods, alternative waveguide implementations and in particular bundling of waveguides runs are evaluated and compared with present harness designs to ascertain potential mass savings.

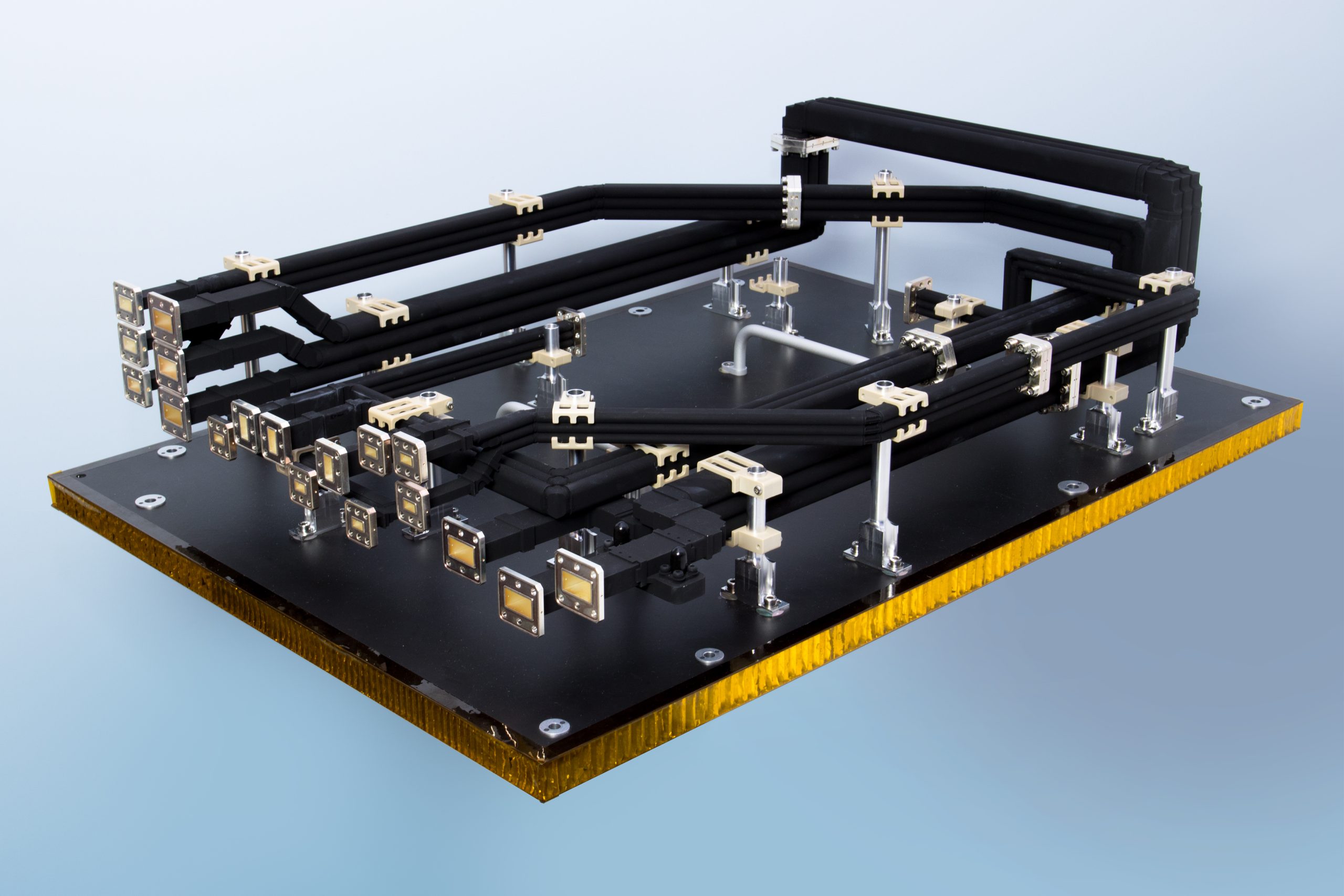

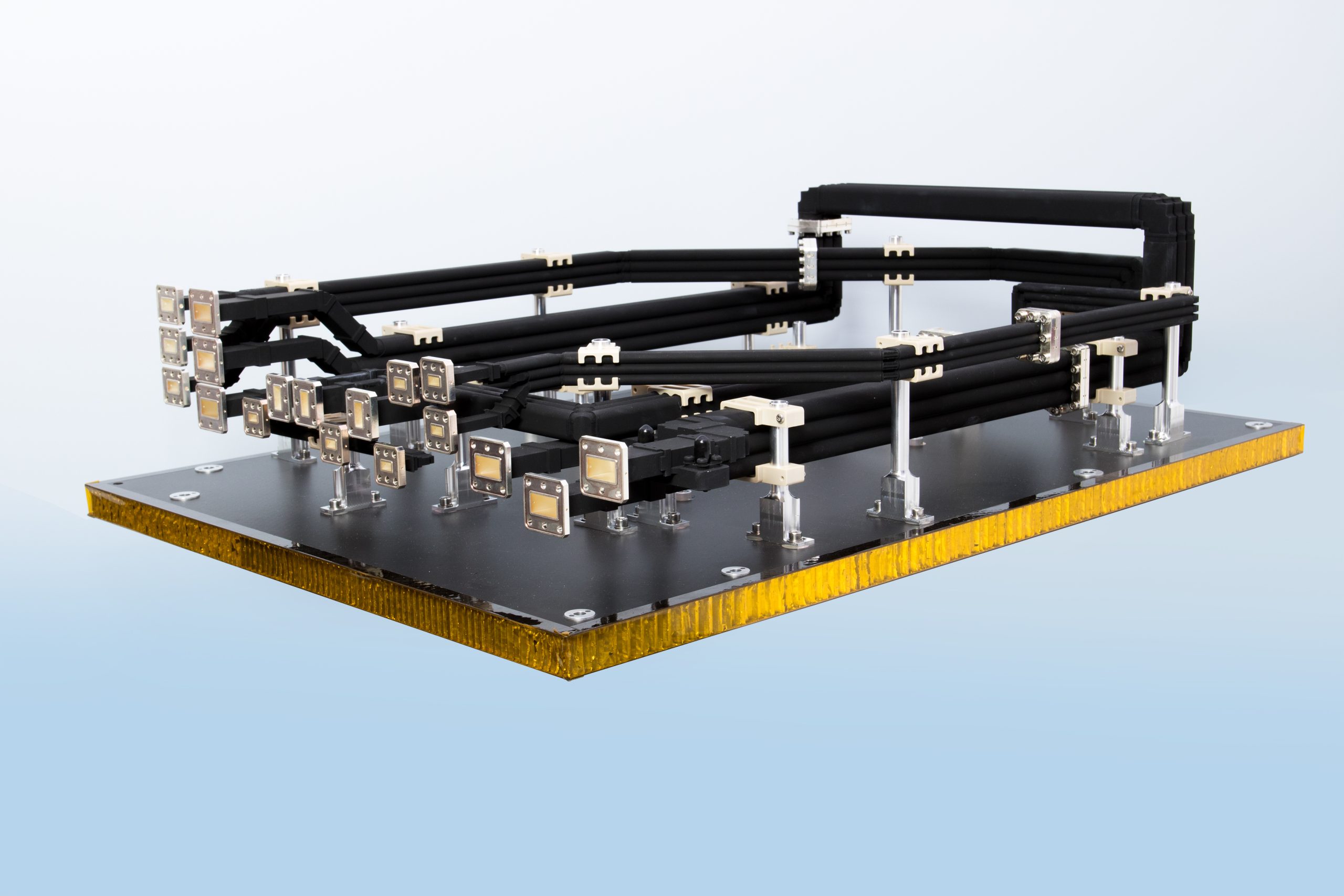

One high power and two low-power waveguide harness breadboards are developed, built and tested for Ku- and Ka-band applications to validate the advantages of the novel solutions. All aspects related to manufacturing, production quality and satellite integration are assessed.

Challenges

Lowest possible mass is a key aspect for satellite hardware design.

Existing harness implementations relying on standard rectangular waveguide designs have reached the limits of performance as well as low mass.

Thus, the project is focussing on new solutions that provide essential mass savings while maintaining the same or better RF performance properties. Additional aspects are

- interfacing of single standard waveguide types of the payload and antenna subsystems, respectively, at almost arbitrary locations

- high-power handling capability

- appropriate installation along pre-defined routings

Finally the developed solution should facilitate handling and integration while providing also an overall cost advantage.

System Architecture

A bundled waveguide harness approach is developed for multi-beam satellite applications providing remarkable mass reductions compared with single standard waveguide interconnections. Several waveguide paths are associated closely in a profile sharing common separation walls. Novel waveguide components (e.g. bends, transformers, etc.) are developed, to allow convenient combination of bundled waveguide sections (with and without flange interconnections) for the realization of arbitrary routed (bundled) waveguide runs as well as interfacing with single standard waveguides at arbitrary locations at the antenna and payload subsystems, respectively. The profiles consider customized cigar-shape cross sections that have been optimized for the dedicated satellite frequency band to maintain lowest possible insertion loss while facilitating the manufacturing properties. The advantages of the novel solution are validated by the development of bundled waveguide harnesses for the Ku‑Rx, Ka-Tx and Ka-Rx frequency bands. The proof includes the manufacturing, integration and testing (RF performance and high power handling capability) of the hardware as well as detailed analyses of mechanical and thermal properties. A comparison of these novel harnesses with comparable traditional implementations demonstrates the essential benefits, namely, considerable mass savings, improved insertion loss and overall lower costs.

Plan

- Review of Manufacturing, Assembly and Mounting Technologies

- Review and Evaluation of RF Transmission and Bundling Concepts

- Lightweight RF Harness Proof of Concept Demonstration

- RF Harness Design

- RF Harness BB Manufacturing

- RF Harness Compliance Testing

- Identification of Limitations and Improvements

Current Status

Completed