PAGE CONTENTS

Objectives

The LCTWTA Dual with EPC evolution (DUAL Evo LCTWTA) designed, manufactured and qualified in this project is dedicated and optimised for the Worldwide SatCom market.

The main objective of this project is to propose a product that is easy to manufacture while being at least a state of the art product in term of performance. It implements some advanced features that make differentiators, either for the final user (power flexibility) or for the satellite manufacturer.

The most significant features or performances are:

-

Power Flexibility : ability to tune in flight the RF power of the TWT.

-

Output power range: Ability to drive two Ka Band 170W RF TWTs

-

Cover of wide range of TMTC interface

-

A very large Vk voltage up to 8 kV

-

Compatible with 5 collectors TWT

Challenges

The main challenges are :

-

first, to design a cheap and easy to manufacture high voltage power supply, in order to be competitive in the main segments of the telecom market,

-

then, to keep high technical performances in terms of Flexibility (Power) and power and frequency range.

Thales Alenia Space in Belgium is a worldwide recognized key actor for its skills and competence in the high voltage field with very significant flight heritage for Single and Dual EPC’s; the main challenge is to keep this position for DUAL Evo LCTWTA product.

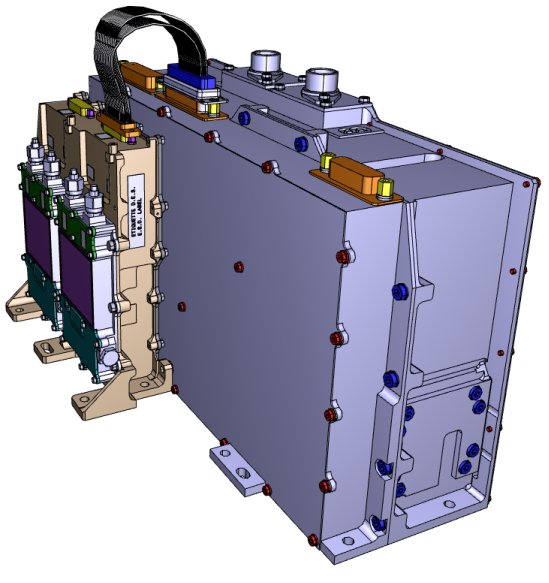

System Architecture

A LCTWTA is a power RF amplifier built around a Travelling Wave Tube (TWT) associated to a Linearizer Driver Limiter Amplifier (LDLA), supplied and controlled by Electronic Power Conditioner (EPC).

The flexible feature of a DUAL Evo LCTWTA consists in the driving of two TWT + one dual LDLA by a unique EPC able to directly manage TWT Power through TM/TC chain. In the flexible power control presented solution, flexibility is shared between EPC and LDLA.

Plan

The Project is divided in two major phases and contract: Dual EPC Evaluation validation phase & LCTWTA Dual with EPC evolution qualification phase;

The first contract is divided in following phases:

-

Phase 1: Selection and definition of the best materials and processes

-

Trials on non-representative test modules (small test vehicles)

-

-

Phase 2: Integration of technological solutions with the EPC EVO architecture

-

Test of representative HV modules (mechanical, thermo-mechanical, thermal models matching)

-

-

Phase 3: EM testing

-

Electrical tests of fully electrically representative HV module (EPC level)

-

The second contract is divided in following main steps:

-

Design / development and validation on Development Model DM, Development of EGSE

-

Return of experience of DM1 and from evaluation validation contract and development of EQM

-

Qualification of EQM

Current Status

The first contract is now closed.

In the second contract, all main steps are closed except qualification phase that is running.