PAGE CONTENTS

Objectives

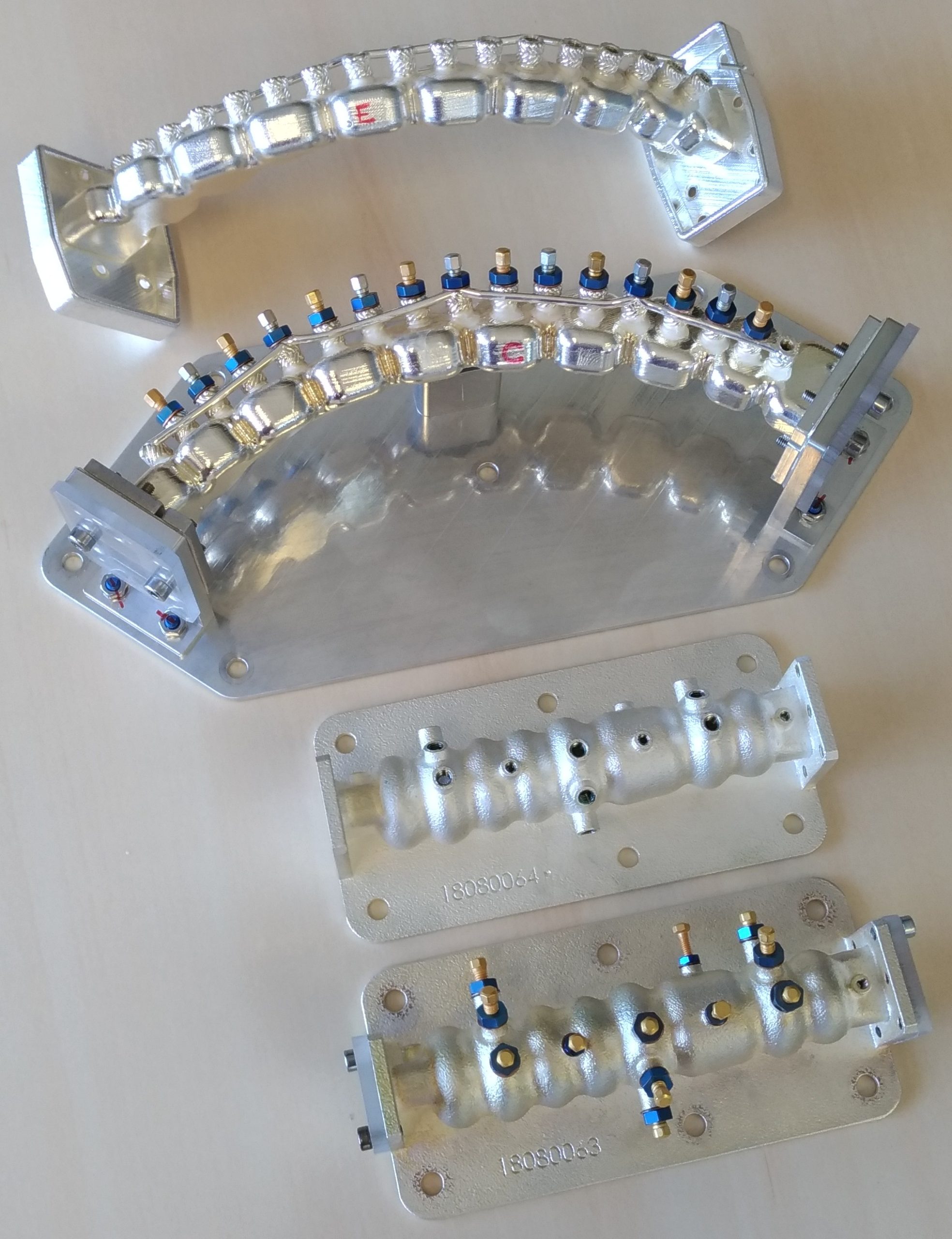

The project aims at combining the capabilities of additive manufacturing with electroforming to offer a viable alternative in the manufacturing of RF passive components such as Ka band filters. These particular filter components have among the highest mechanical tolerance and surface roughness requirements. Furthermore, these components show quantifiable RF response to environmental changes (temperature, vibrations, stress…), as well as high power RF (PIM), which can be used as a precise tool to evaluate the stability of an employed manufacturing technology with respect to space relevant environmental conditions. The aim of this study is to demonstrate the successful performance and resistance to space relevant environmental conditions of components featuring:

- Lower costs (at least 25% cheaper)

- Lower lead time (at least 25% shorter)

- Increased flexibility in manufacture-able RF designs

- Mass savings

Challenges

- Additive manufacturing of a mandrel

- Mandrel post processing

- Mandrel conductivizing

- Electroforming

- Mandrel removal

- Interfaces machining

- Additive manufacturing of the skeleton in Aluminium

- Surface preparation by chemical means to ensure good adhesion of metal plating

- Electroless plating of the component with a sufficient thickness (depending on the skin depth) in order to become RF functional.

System Architecture

- High Power Ka band ODMUX operating at 20 GHz and needed in high volumes

- Ka band CMUX (low power, dual mode) operating at 30 GHz and needed in high volumes

Plan

Current Status

Project has been completed/developed from Feasibility Study to Demo.